Development and optimization of a microbial fuel cells consortium by response surface methodology for the effective reduction of hexavalent chromium with power generation

DOI:

https://doi.org/10.18006/2025.13(2).239.257Keywords:

Response surface methodology, Leather industry wastewater, Microbial fuel cells, Power generation, Hexavalent chromium, Environmental sustainabilityAbstract

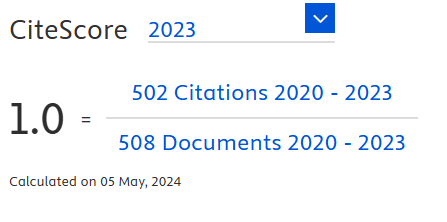

Microbial fuel cells (MFCs) present a promising green technology for wastewater treatment while simultaneously generating power. However, for MFCs to be sustainable and scalable, they require significant technological and operational improvements. This study aimed to optimize the MFC process using Response Surface Methodology (RSM), which integrates modeling techniques, optimization methodologies, experimental design, and analysis. RSM was applied to evaluate the interactions among three independent variables: the working volume of wastewater, the buffer's pH, and the bacterial consortia's inoculum size. Double-chambered MFCs were inoculated with various bacterial strains, including Pseudomonas stutzeri, Microbacterium algeriense, and Bacillus stratosphericus. The results indicated that MFC performance was significantly influenced by the interactions between (i) the volume of wastewater and buffer pH, (ii) the volume of wastewater and inoculum size, and (iii) buffer pH and inoculum size. The RSM findings identified the optimal conditions for power generation and hexavalent chromium (Cr6+) reduction as approximately 80% working volume of wastewater, a buffer pH of 6.9, and a 26% inoculum size of bacterial consortia. A strong correlation between the model predictions and experimental results confirmed the model's accuracy in capturing the interactions among the independent factors. These findings demonstrated the effectiveness of RSM in optimizing the performance of MFCs and provided valuable insights for the future development of sustainable MFC-based wastewater treatment systems.

References

Asoo, H. R., Alakali, J. S., Ikya, J. K., & Yusufu, M. I. (2024). Historical background of RSM. In V. Silva, & J. Sousa (Eds.) Cardoso Response Surface Methods-Theory, Applications and Optimization Techniques. IntechOpen. https://doi.org/10.5772/ intechopen.1005302

Behera, M., Jana, P. S., More, T. T., & Ghangrekar, M. M. (2010). Rice mill wastewater treatment in microbial fuel cells fabricated using proton exchange membrane and earthen pot at different pH. Bioelectrochemistry, 79(2), 228-233. https://doi.org/10.1016/ j.bioelechem.2010.06.002. DOI: https://doi.org/10.1016/j.bioelechem.2010.06.002

Beretta, G., Daghio, M., Espinoza Tofalos, A., Franzetti, A., Mastorgio, A. F., Saponaro, S., & Sezenna, E. (2020). Microbial assisted hexavalent chromium removal in bioelectrochemical systems. Water, 12(2), 466. https://doi.org/10.3390/w12020466. DOI: https://doi.org/10.3390/w12020466

Chang, S. H., Wu, C. H., Wang, R. C., & Lin, C. W. (2017). Electricity production and benzene removal from groundwater using low-cost mini tubular microbial fuel cells in a monitoring well. Journal of Environmental Management, 193, 551-557. https://doi.org/10.1016/j.jenvman.2017.02.053. DOI: https://doi.org/10.1016/j.jenvman.2017.02.053

Choudhury, P., Bhunia, B., & Bandyopadhyaya, T. K. (2021). Screening technique on the selection of potent microorganisms for operation in microbial fuel cell for generation of power. Journal of Electrochemical Science and Engineering, 11(2), 129-142. https://doi.org/10.5599/jese.924. DOI: https://doi.org/10.5599/jese.924

Cristiani, L., Zeppilli, M., Feriaud, D., Marandola, C., Papini, M. P., et al. (2024). Enhancing energy efficiency and H2 production in lab-scale dual chamber microbial electrolysis cells: A focus on catholyte composition and voltage losses. Journal of Environmental Chemical Engineering, 12(1), 111782. https://doi.org/10.1016/j.jece.2023.111782. DOI: https://doi.org/10.1016/j.jece.2023.111782

Devi, A., Ferreira, L.F.R., Saratale, G.D., Mulla, S.I., More, N., & Bharagava, R.N. (2022). Microbe-assisted phytoremediation of environmental contaminants. In K. Kuldeep Bauddh, & Y. Ma (Eds.) Advances in microbe-assisted phytoremediation of polluted sites (pp. 3-26). Elsevier Publication. https://doi.org/10.1016/B978-0-12-823443-3.00001-6. DOI: https://doi.org/10.1016/B978-0-12-823443-3.00001-6

Devi, A., Saran, C., & Bharagava, R.N. (2023a). Use of secondary treated tannery wastewater as nutrient source to grow cyanobacteria and microalgae and evaluation of its effectivity as liquid biofertilizer on Vigna radiata L seeds. Journal of Applied Science, Innovation & Technology, 2 (2), 82-89.

Devi, A., Saran, C., Verma, M., Saratale, G.D., Ferreira, L.F.R., More, N., & Bharagava, R.N. (2024). Simultaneous Extraction, Separation and Characterization of Biomolecules from Microalgal Biomass. In N. Bharadvaja, L. Kumar, S. Pandit, S. Banerjee, & R. Anand (Eds) Recent Trends and Developments in Algal Biofuels and Biorefinery (pp. 147-170). Springer Nature Switzerland. https://doi.org/10.1007/978-3-031-52319-9_7. DOI: https://doi.org/10.1007/978-3-031-52319-9_7

Devi, A., Verma, M., Saratale, G. D., Saratale, R. G., Ferreira, L. F. R., Mulla, S. I., & Bharagava, R. N. (2023b). Microalgae: A green eco-friendly agents for bioremediation of tannery wastewater with simultaneous production of value-added products. Chemosphere, 336, 139192. https://doi.org/10.1016/ j.chemosphere.2023.139192. DOI: https://doi.org/10.1016/j.chemosphere.2023.139192

Dubey, P., Farooqui, A., Patel, A., & Srivastava, P. K. (2024). Microbial innovations in chromium remediation: mechanistic insights and diverse applications. World Journal of Microbiology and Biotechnology, 40(5), 151. https://doi.org/10.1007/s11274-024-03936-w. DOI: https://doi.org/10.1007/s11274-024-03936-w

Elahi, A., Ajaz, M., Rehman, A., Vuilleumier, S., Khan, Z., & Hussain, S. Z. (2019). Isolation, characterization, and multiple heavy metal-resistant and hexavalent chromium-reducing Microbacterium testaceum B-HS2 from tannery effluent. Journal of King Saud University-Science, 31(4), 1437-1444. https://doi.org/10.1016/j.jksus.2019.02.007. DOI: https://doi.org/10.1016/j.jksus.2019.02.007

El-Naggar, N. E. A., El-Khateeb, A. Y., Ghoniem, A. A., El-Hersh, M. S., & Saber, W. I. (2020). Innovative low-cost biosorption process of Cr6+ by Pseudomonas alcaliphila NEWG-2. Scientific Reports, 10(1), 14043. https://doi.org/10.1038/s41598-020-70473-5. DOI: https://doi.org/10.1038/s41598-020-70473-5

Estrada-Arriaga, E. B., Hernández-Romano, J., García-Sánchez, L., Garcés, R. A. G., Bahena-Bahena, E. O., Guadarrama-Pérez, O., & Chavez, G. E. M. (2018). Domestic wastewater treatment and power generation in continuous flow air-cathode stacked microbial fuel cell: Effect of series and parallel configuration. Journal of environmental management, 214, 232-241. https://doi.org/10.1016/j.jenvman.2018.03.007. DOI: https://doi.org/10.1016/j.jenvman.2018.03.007

Fan, Y., Hu, H., & Liu, H. (2007). Sustainable power generation in microbial fuel cells using bicarbonate buffer and proton transfer mechanisms. Environmental Science & Technology, 41(23), 8154-8158. https://doi.org/10.1021/es071739c. DOI: https://doi.org/10.1021/es071739c

Gad, S., Ayakar, S., & Adivarekar, R. (2024). Formulation and characterization of bacterial consortium for efficient lignocellulosic waste degradation. Journal of Environmental Chemical Engineering, 12(3), 112619. https://doi.org/10.1016/ j.jece.2024.112619. DOI: https://doi.org/10.1016/j.jece.2024.112619

Gao, C. H., Cao, H., Cai, P., & Sørensen, S. J. (2021). The initial inoculation ratio regulates bacterial coculture interactions and metabolic capacity. The ISME journal, 15(1), 29-40. https://doi.org/10.1038/s41396-020-00751-7. DOI: https://doi.org/10.1038/s41396-020-00751-7

Greenman, J., Gajda, I., You, J., Mendis, B. A., Obata, O., Pasternak, G., & Ieropoulos, I. (2021). Microbial fuel cells and their electrified biofilms. Biofilm, 3, 100057. https://doi.org/10.1016/j.bioflm.2021.100057. DOI: https://doi.org/10.1016/j.bioflm.2021.100057

Gude, V. G. (2016). Wastewater treatment in microbial fuel cells–an overview. Journal of cleaner production, 122, 287-307. https://doi.org/10.1016/j.jclepro.2016.02.022. DOI: https://doi.org/10.1016/j.jclepro.2016.02.022

Harnisch, F., Deutzmann, J. S., Boto, S. T., & Rosenbaum, M. A. (2024). Microbial electrosynthesis: opportunities for microbial pure cultures. Trends in Biotechnology, 42 (8), 1035-1042. https://doi.org/10.1016/j.tibtech.2024.02.004. DOI: https://doi.org/10.1016/j.tibtech.2024.02.004

Hassan, R. Q. U., Tahir, M. M., Waheed, S., Naimat, S., & Ullah, M. (2024). The Critical Role of Phosphate Buffers in Cellular Function: From Homeostasis to Disease. Biology Bulletin Reviews, 14(Suppl 3), S211-S218. https://doi.org/10.1134/S2079086424600723. DOI: https://doi.org/10.1134/S2079086424600723

Islam, M. A., Ong, H. R., Ethiraj, B., Cheng, C. K., & Khan, M. M. R. (2018). Optimization of coculture inoculated microbial fuel cell performance using response surface methodology. Journal of Environmental Management, 225, 242-251. https://doi.org/10.1016/j.jenvman.2018.08.002. DOI: https://doi.org/10.1016/j.jenvman.2018.08.002

Islam, M. A., Woon, C. W., Ethiraj, B., Cheng, C. K., Yousuf, A., & Khan, M. M. R. (2017). Ultrasound driven biofilm removal for stable power generation in microbial fuel cell. Energy & Fuels, 31(1), 968-976. https://doi.org/10.1021/acs.energyfuels.6b02294. DOI: https://doi.org/10.1021/acs.energyfuels.6b02294

Kaiser, R., & Park, J. C. (2024). Machine learning optimization of operating parameters to achieve high power density and efficiency of polymer electrolyte membrane fuel cell. Chemical Engineering Science, 297, 120309. https://doi.org/10.1016/j.ces.2024.120309. DOI: https://doi.org/10.1016/j.ces.2024.120309

Kashyap, B.K., Saran, C., Solanki, M.K., & Divvela, P.K. (2023). Emerging Frontiers of Microbes as Liquid Waste Recycler . In: B.K. Kashyap, & M.K. Solanki, (Eds.) Current Research Trends and Applications in Waste Management. Springer, Singapore. https://doi.org/10.1007/978-981-99-3106-4_1. DOI: https://doi.org/10.1007/978-981-99-3106-4_1

Madani, S., Gheshlaghi, R., Mahdavi, M. A., Sobhani, M., & Elkamel, A. (2015). Optimization of the performance of a double-chamber microbial fuel cell through factorial design of experiments and response surface methodology. Fuel, 150, 434-440. https://doi.org/10.1016/j.fuel.2015.02.039. DOI: https://doi.org/10.1016/j.fuel.2015.02.039

Mei, X., Guo, C., Liu, B., Tang, Y., & Xing, D. (2015). Shaping of bacterial community structure in microbial fuel cells by different inocula. Rsc Advances, 5(95), 78136-78141. https://doi.org/10.1039/C5RA16382J. DOI: https://doi.org/10.1039/C5RA16382J

Mishra, S., Chen, S., Saratale, G. D., Saratale, R. G., Ferreira, L. F. R., Bilal, M., & Bharagava, R. N. (2021). Reduction of hexavalent chromium by Microbacterium paraoxydans isolated from tannery wastewater and characterization of its reduced products. Journal of Water Process Engineering, 39, 101748. https://doi.org/10.1016/j.jwpe.2020.101748. DOI: https://doi.org/10.1016/j.jwpe.2020.101748

Moradi, M., Song, Z., Nie, X., Yan, M., & Hu, F.Q. (2016). Investigation of bacterial attachment and biofilm formation of two different Pseudoalteromonas species: Comparison of different methods. International Journal of Adhesion and Adhesives, 65, 70-78. DOI: https://doi.org/10.1016/j.ijadhadh.2015.11.004

Mu, C., Wang, L., & Wang, L. (2020). Performance of lab-scale microbial fuel cell coupled with unplanted constructed wetland for hexavalent chromium removal and electricity production. Environmental Science and Pollution Research, 27(20), 25140-25148. https://doi.org/10.1007/s11356-020-08982-z. DOI: https://doi.org/10.1007/s11356-020-08982-z

Pandya, R. S., Kaur, T., Bhattacharya, R., Bose, D., & Saraf, D. (2024). Harnessing microorganisms for bioenergy with Microbial Fuel Cells: Powering the future. Water-Energy Nexus, 7, 1-12. https://doi.org/10.1016/j.wen.2023.11.004. DOI: https://doi.org/10.1016/j.wen.2023.11.004

Pant, D., Van Bogaert, G., Diels, L., & Vanbroekhoven, K. (2010). A review of the substrates used in microbial fuel cells (MFCs) for sustainable energy production. Bioresource Technology, 101(6), 1533-1543. https://doi.org/10.1016/j.biortech.2009.10.017. DOI: https://doi.org/10.1016/j.biortech.2009.10.017

Puig, S., Serra, M., Coma, M., Cabré, M., Balaguer, M. D., & Colprim, J. (2010). Effect of pH on nutrient dynamics and electricity production using microbial fuel cells. Bioresource Technology, 101(24), 9594-9599. https://doi.org/10.1016/j.biortech.2010.07.082. DOI: https://doi.org/10.1016/j.biortech.2010.07.082

Ramli, N. N., Kurniawan, S. B., Ighalo, J. O., Mohd Said, N. S., Marsidi, N., et al. (2023). A review of the treatment technologies for hexavalent chromium contaminated water. BioMetals, 36(6), 1189-1219. https://doi.org/10.1007/s10534-023-00512-x. DOI: https://doi.org/10.1007/s10534-023-00512-x

Rao, A., Haque, S., El-Enshasy, H. A., Singh, V., & Mishra, B. N. (2019). RSM–GA based optimization of bacterial PHA production and in-silico modulation of citrate synthase for enhancing PHA production. Biomolecules, 9(12), 872. https://doi.org/10.3390/ biom9120872. DOI: https://doi.org/10.3390/biom9120872

Rathinavel, N., Samuel, J. O. E., Veleeswaran, A., Nallathambi, S., Ponnuchamy, K., et al. (2024). Exploring the Key factors enhancing the Microbial Fuel Cell performance. Process Safety and Environmental Protection, 193, 385-402. https://doi.org/10.1016/j.psep.2024.10.090. DOI: https://doi.org/10.1016/j.psep.2024.10.090

Reji, M., & Kumar, R. (2022). Response surface methodology (RSM): An overview to analyze multivariate data. Indian Journal of Microbiology Research, 9, 241-248. https://doi.org/10.18231/j.ijmr.2022.042. DOI: https://doi.org/10.18231/j.ijmr.2022.042

Sabina-Delgado, A., Kamaraj, S. K., Hernández-Montoya, V., Valdés-Valadez, J. O., Prieto-Muñoz, R., Cervantes, F. J., & Montes-Morán, M. Á. (2024). Optimization of the microbial fuel cells operation for wastewater treatment by using cylindrical ceramic membranes. International Journal of Hydrogen Energy, 72, 400-411. https://doi.org/10.1016/j.ijhydene.2024.05.377. DOI: https://doi.org/10.1016/j.ijhydene.2024.05.377

Sadabad, H. R., & Gholikandi, G. B. (2017). Harvesting direct electricity from municipal waste-activated sludge simultaneous with its aerobic stabilization process: Investigation and optimization. Journal of environmental chemical engineering, 5(1), 1174-1185. https://doi.org/10.1016/j.jece.2017.01.030. DOI: https://doi.org/10.1016/j.jece.2017.01.030

Samudro, G., Imai, T., & Hung, Y. T. (2021). Enhancement of power generation and organic removal in double anode chamber designed dual-chamber microbial fuel cell (Dac-dcmfc). Water, 13(21), 2941. https://doi.org/10.3390/w13212941. DOI: https://doi.org/10.3390/w13212941

Sanchez-Hachair, A., & Hofmann, A. (2018). Hexavalent chromium quantification in solution: Comparing direct UV–visible spectrometry with 1, 5-diphenylcarbazide colorimetry. Comptes Rendus Chimie, 21(9), 890-896. https://doi.org/10.1016/j.crci.2018.05.002. DOI: https://doi.org/10.1016/j.crci.2018.05.002

Saran, C., Devi, A., Saratale, G.D., Ferreira, L.F.R., & Bharagava, R.N. (2024a) Bioenergy Generation and Cogeneration from Algae-Based Biorefineries. In S.K. Arya, M. Khatri, & G. Singh (Eds.) Value Added Products From Bioalgae Based Biorefineries: Opportunities and Challenges (pp. 189-211). Springer Nature Singapore. https://doi.org/10.1007/978-981-97-1662-3_9. DOI: https://doi.org/10.1007/978-981-97-1662-3_9

Saran, C., Devi, A., Verma, M., Saratale, G. D., Ferreira, L. F. R., More, N., & Bharagava, R. N. (2024b). A Continuous System of Biofuel Production from Microalgal Biomass. In N. Bharadvaja, L. Kumar, S. Pandit, S. Banerjee, & R. Anand (eds) Recent Trends and Developments in Algal Biofuels and Biorefinery. Environmental Science and Engineering (pp. 77-106). Cham: Springer Nature Switzerland. https://doi.org/10.1007/978-3-031-52319-9_4. DOI: https://doi.org/10.1007/978-3-031-52319-9_4

Saran, C., Purchase, D., Saratale, G. D., Saratale, R. G., Ferreira, L. F. R., et al. (2023). Microbial fuel cell: A green eco-friendly agent for tannery wastewater treatment and simultaneous bioelectricity/power generation. Chemosphere, 312, 137072. https://doi.org/10.1016/j.chemosphere.2022.137072. DOI: https://doi.org/10.1016/j.chemosphere.2022.137072

Sarankumar, R. K., Arulprakash, A., Devanesan, S., Selvi, A., AlSalhi, M. S., Rajasekar, A., & Ahamed, A. (2020). Bioreduction of hexavalent chromium by chromium resistant alkalophilic bacteria isolated from tannery effluent. Journal of King Saud University-Science, 32(3), 1969-1977. https://doi.org/10.1016/ j.jksus.2020.02.010. DOI: https://doi.org/10.1016/j.jksus.2020.02.010

Sathishkumar, K., Murugan, K., Benelli, G., Higuchi, A., & Rajasekar, A. (2017). Bioreduction of hexavalent chromium by Pseudomonas stutzeri L1 and Acinetobacter baumannii L2. Annals of Microbiology, 67, 91-98. https://doi.org/10.1007/s13213-016-1240-4. DOI: https://doi.org/10.1007/s13213-016-1240-4

Satpati, G. G., Devi, A., Kundu, D., Dikshit, P. K., Saravanabhupathy, S., et al. (2024). Synthesis, delineation and technological advancements of algae biochar for sustainable remediation of the emerging pollutants from wastewater-a review. Environmental Research, 258, 119408. https://doi.org/10.1016/ j.envres.2024.119408. DOI: https://doi.org/10.1016/j.envres.2024.119408

Segundo, R. F., De La Cruz-Noriega, M., Cabanillas-Chirinos, L., Otiniano, N. M., Soto-Deza, N., Rojas-Villacorta, W., & De La Cruz-Cerquin, M. (2024). The Potential Use of Pseudomonas stutzeri as a Biocatalyst for the Removal of Heavy Metals and the Generation of Bioelectricity. Fermentation, 10(2), 113. https://doi.org/10.3390/fermentation10020113. DOI: https://doi.org/10.3390/fermentation10020113

Sevda, S., & Sreekrishnan, T. R. (2012). Effect of salt concentration and mediators in salt bridge microbial fuel cell for electricity generation from synthetic wastewater. Journal of Environmental Science and Health, Part A, 47(6), 878-886. https://doi.org/10.1080/10934529.2012.665004. DOI: https://doi.org/10.1080/10934529.2012.665004

Singh, A., & Kaushik, A. (2021). Sustained energy production from wastewater in microbial fuel cell: effect of inoculum sources, electrode spacing and working volume. 3 Biotech, 11(7), 344. https://doi.org/10.1007/s13205-021-02886-6. DOI: https://doi.org/10.1007/s13205-021-02886-6

Singh, V., & Tripathi, C. K. M. (2008). Production and statistical optimization of a novel olivanic acid by Streptomyces olivaceus MTCC 6820. Process Biochemistry, 43(11), 1313-1317. https://doi.org/10.1016/j.procbio.2008.07.015. DOI: https://doi.org/10.1016/j.procbio.2008.07.015

Sophia, A. C., & Saikant, S. (2016). Reduction of chromium (VI) with energy recovery using microbial fuel cell technology. Journal of Water Process Engineering, 11, 39-45. https://doi.org/10.1016/j.jwpe.2016.03.006. DOI: https://doi.org/10.1016/j.jwpe.2016.03.006

Srivastava, A., Singh, V., Haque, S., Pandey, S., Mishra, M., et al. (2018). Response surface methodology-genetic algorithm based medium optimization, purification, and characterization of cholesterol oxidase from Streptomyces rimosus. Scientific reports, 8(1), 10913. https://doi.org/10.1038/s41598-018-29241-9. DOI: https://doi.org/10.1038/s41598-018-29241-9

Sun, D., Cheng, S., Wang, A., Li, F., Logan, B. E., & Cen, K. (2015). Temporal-spatial changes in viabilities and electrochemical properties of anode biofilms. Environmental Science & Technology, 49(8), 5227-5235. https://doi.org/10.1021/acs.est.5b00175. DOI: https://doi.org/10.1021/acs.est.5b00175

Sun, Y., Li, H., Guo, S., & Li, C. (2024). Metal-based cathode catalysts for electrocatalytic ORR in microbial fuel cells: A

review. Chinese Chemical Letters, 35(5), 109418. https://doi.org/10.1016/j.cclet.2023.109418. DOI: https://doi.org/10.1016/j.cclet.2023.109418

Tan, H., Wang, C., Zeng, G., Luo, Y., Li, H., & Xu, H. (2020). Bioreduction and biosorption of Cr (VI) by a novel Bacillus sp. CRB-B1 strain. Journal of hazardous Materials, 386, 121628. https://doi.org/10.1016/j.jhazmat.2019.121628. DOI: https://doi.org/10.1016/j.jhazmat.2019.121628

Thacker, U., & Madamwar, D. (2005). Reduction of toxic chromium and partial localization of chromium reductase activity in bacterial isolate DM1. World Journal of Microbiology and Biotechnology, 21, 891-899. https://doi.org/10.1007/s11274-004-6557-7. DOI: https://doi.org/10.1007/s11274-004-6557-7

Wang, J., Khan, S. A., Yasmin, S., Alam, M. M., Liu, H., et al. (2023). Central composite design (CCD)-Response surface methodology (RSM) for modeling and simulation of MWCNT-water nanofluid inside hexagonal cavity: Application to electronic cooling. Case Studies in Thermal Engineering, 50, 103488. https://doi.org/10.1016/j.csite.2023.103488. DOI: https://doi.org/10.1016/j.csite.2023.103488

Zadeh, P. G., Rezania, S., Fattahi, M., Dang, P., Vasseghian, Y., & Aminabhavi, T. M. (2024). Recent advances in microbial fuel cell technology for energy generation from wastewater sources. Process Safety and Environmental Protection, 189, 425-439. https://doi.org/10.1016/j.psep.2024.06.077. DOI: https://doi.org/10.1016/j.psep.2024.06.077

Zhang, J., Zhang, E., Scott, K., & Burgess, J. G. (2012). Enhanced electricity production by use of reconstituted artificial consortia of estuarine bacteria grown as biofilms. Environmental Science & Technology, 46(5), 2984-2992. https://doi.org/10.1021/es2020007. DOI: https://doi.org/10.1021/es2020007

Downloads

Published

How to Cite

License

Copyright (c) 2025 Journal of Experimental Biology and Agricultural Sciences

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.