Heat Pump Drying of Nutmeg Pericarp: Engineering Properties, Drying Kinetics, and Haghi-Angiz-II Modelling for Process Optimisation

DOI:

https://doi.org/10.18006/2025.13(1).116.124Keywords:

Nutmeg pericarp, Heat pump drying, Drying kinetics, Mathematical modelling, R studio, Haghi and Angiz-II modelling, Moisture diffusivityAbstract

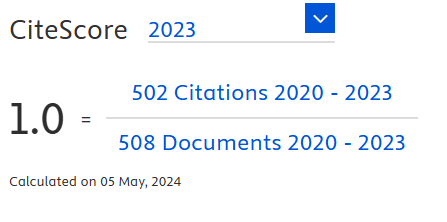

This study investigates the engineering properties of nutmeg pericarp and develops a mathematical model to describe its drying behavior in a heat pump dryer. Nutmeg pericarp, an underutilized part of the nutmeg fruit, is a rich source of phytochemicals but is highly perishable, necessitating immediate postharvest drying for further processing. Drying experiments were conducted at a controlled temperature of 55°C and a relative humidity of 37%. Regression modeling was used to analyze the drying kinetics, utilizing MATLAB R2020a and R Studio software. Various statistical metrics, including the coefficient of determination (R²), adjusted R², and root mean square error (RMSE), were evaluated to determine the predictive accuracy of different thin-layer drying models. Among the models assessed, the Haghi and Angiz-II model best fit the experimental data, achieving the highest R² value of 0.999. A scatter plot comparing the experimental and predicted moisture ratios further confirmed the reliability of this model. The effective moisture diffusivity ranged from 2.1 × 10⁻⁸ to 9.08 × 10⁻⁸ m²/s. Additionally, the quality assessment indicates that heat pump drying positively influences the key quality attributes of nutmeg pericarp.

References

Adiletta, G., Petriccione, M., Liguori, L., Pizzolongo, F., Romano, R., & Di Matteo, M. (2018). Study of pomological traits and physico-chemical quality of pomegranate (Punica granatum L.) genotypes grown in Italy. European Food Research and Technology, 244(8), 1427-1438. DOI: https://doi.org/10.1007/s00217-018-3056-x

Chong, C. H., Law, C. L., Figiel, A., Wojdylo, A., & Oziembłowski, M. (2013). Colour, phenolic content and antioxidant capacity of some fruits dehydrated by a combination of different methods. Food Chemistry, 141, 3889-3896. http://dx.doi.org/10.1016/j.foodchem.2013.06.042. DOI: https://doi.org/10.1016/j.foodchem.2013.06.042

Crank, J. (1975). The mathematics of diffusion. Oxford University Press. 44p.

Han, L., & Jin, T. X. (2024). Effects of combined vacuum and heat pump drying on drying characteristics and physicochemical properties of pineapple. LWT- Food Science and Technology, 192, 115727. https://doi.org/10.1016/j.lwt.2024.115727. DOI: https://doi.org/10.1016/j.lwt.2024.115727

Ertekin, C., & Firat, M. Z. (2015). A Comprehensive Review of Thin Layer Drying Models Used in Agricultural Products. Critical Reviews in Food Science and Nutrition, 57 (4), 701-717. DOI: https://doi.org/10.1080/10408398.2014.910493

Haghi, A.K., & Angiz, F.Z. (2007). Heat and mass transfer in thermal drying of wool: a theoretical approach. The Proceedings of the 5th Asia-Pasific Drying Conference, 1, 443-448. DOI: https://doi.org/10.1142/9789812771957_0065

Hawlader, M.N.A., Perera, C.O., & Tian, M. (2006). Comparison of the retention of 6-gingerol in drying of ginger under modified atmosphere heat pump drying and other drying methods. Drying Technology, 24(1), 51–56. https://doi.org/10.1080/ 07373930500538675. DOI: https://doi.org/10.1080/07373930500538675

Kumar, V., Sharma, H. K., & Kumar, N. (2022). Engineering Properties of Foods. In H. K. Sharma, & N. Kumar, (Eds). Agro-Processing and Food Engineering: Operational and Application Aspects (pp. 23-80). Singapore: Springer Singapore. DOI: https://doi.org/10.1007/978-981-16-7289-7_2

Maskan, M. (2001). Kinetics of colour change of kiwifruits during hot air and microwave drying. Journal of Food Engineering, 48,169-175. DOI: https://doi.org/10.1016/S0260-8774(00)00154-0

Murakonda, S., Patel, G., & Dwivedi, M. (2022) Characterization of engineering properties and modeling mass and fruit fraction of wood apple (Limonia acidissima) fruit for postharvest processing. Journal of the Saudi Society of Agricultural Sciences, 21(4), 267-277 https://doi.org/10.1016/j.jssas.2021.09.005 DOI: https://doi.org/10.1016/j.jssas.2021.09.005

Murali, S., Delfiya, D. S. A., Kumar, K. S., Kumar, L. R. G., Nilavan, S. E., Amulya, P. R., & Samuel, M. P. (2021). Mathematical Modeling of Drying Kinetics and Quality Characteristics of Shrimps Dried under a Solar–LPG Hybrid Dryer. Journal of Aquatic Food Product Technology, 30(5), 561–578. https://doi.org/10.1080/10498850.2021.1901814 DOI: https://doi.org/10.1080/10498850.2021.1901814

Nadian, M. H., Rafiee, S., Aghbashlo, M. S., & Mohtasebi, S. S. (2015). Continuous real-time monitoring and neural network modeling of apple slices color changes during hot air drying. Food and Bioproducts Processing, 94, 263-274. https://doi.org/10.1016/j.fbp.2014.03.005. DOI: https://doi.org/10.1016/j.fbp.2014.03.005

Nkhata S. G. (2020). Total color change (ΔE∗) is a poor estimator of total carotenoids lost during postharvest storage of biofortified maize grains. Heliyon, 6(10), e05173. https://doi.org/10.1016/ j.heliyon.2020.e05173. DOI: https://doi.org/10.1016/j.heliyon.2020.e05173

Olanipekun, B. F., Tunde-Akintunde, T. Y., Oyelade, O. J., Adebisi, M. G., & Adenaya, T. A. (2014). Mathematical modelling of thin-layer pineapple drying. Journal of Food Processing and Preservation, 39, 1431-1441.doi:10.1111/jfpp.12362. DOI: https://doi.org/10.1111/jfpp.12362

Patel K. K., & Kar, A. (2012). Heat pump assisted drying of agricultural produce-an overview. Journal of e Food Science and Technology, 49(2), 142-60. doi: 10.1007/s13197-011-0334. DOI: https://doi.org/10.1007/s13197-011-0334-z

Periasamy, G., Karim, A., Gibrelibanos, M., Gebremedhin, G., & Gilani, A.H. (2016). Nutmeg (Myristica fragrans Houtt.) Oils, In: V. R. Preedy (ed.) Essential Oils in Food Preservation, Flavor and Safety (pp. 607–616). Elsevier. doi:10.1016/B978-0-12-416641-7.00069-9. DOI: https://doi.org/10.1016/B978-0-12-416641-7.00069-9

Sahay, K. M., & Singh, K. K. (2009). Unit operations in Agricultural Processing. Vikas Publishing house PVT LTD. New Delhi. pp: 7-8.

Salehi, F., & Kashaninejad, M. (2018). Modeling of moisture loss kinetics and color changes in the surface of lemon slice during the combined infrared-vacuum drying. Information Processing in Agriculture, 5(4), 516-523. DOI: https://doi.org/10.1016/j.inpa.2018.05.006

Suwarda, R., Suneth, R.F., Wahid, & Sondari, D. (2021). Potential and opportunities of nutmeg pericarp as functional foods. E3S Web of Conferences, 306, 04007. doi:10.1051/e3sconf/202130604007. DOI: https://doi.org/10.1051/e3sconf/202130604007

Tunçkal, C. (2020). Investigation of performance and drying kinetics of the closed, partially open, and open heat pump drying systems. Journal of Food Process Engineering, 43(12), e13566. DOI: https://doi.org/10.1111/jfpe.13566

Tunckal, C., & Doymaz, İ. (2020). Performance analysis and mathematical modelling of banana slices in a heat pump drying system. Renewable Energy, 150, 918–923. doi:10.1016/j.renene.2020.01.040. DOI: https://doi.org/10.1016/j.renene.2020.01.040

Vadivambal, R., & Jayas, D. S. (2007). Changes in quality of microwavetreated agricultural products-a review. Biosystems Engineering, 98, 1–16. doi:10.1016/j.biosystemseng.2007.06.006. DOI: https://doi.org/10.1016/j.biosystemseng.2007.06.006

Van Gils, C., & Cox, P.A. (1994). Ethnobotany of nutmeg in the Spice Islands. Journal of Ethnopharmacology, 42, 117–124. https://doi.org/10.1016/0378-8741(94)90105-8. DOI: https://doi.org/10.1016/0378-8741(94)90105-8

Venu, V., Vipin P. R., & Prajitha N. K. (2023). A Comparative Analytical Study of Many Regression Model Approaches, Arima Model and a Hybrid Model for Forecasting Area, Production, and Productivity of Coconut in Kerala, India. Current Journal of Applied Science and Technology, 42(40), 37-49. DOI: https://doi.org/10.9734/cjast/2023/v42i404260

Venu,V., Anjitha, P.K., Vipin, P.R., Ramdas, E.R., Senthilkumar, R., & Sreenath, B. (2024). Temporal Trends and Future Projections: A Deep Dive into India’s Buffalo Milk Production Through Time Series Modelling. Asian Journal of Dairy and Food Research, 43(3), 1-9 doi: 10.18805/ajdfr.DR-2199. DOI: https://doi.org/10.18805/ajdfr.DR-2199

Vidinamo, F., Fawzia, S., & Karim, M.A. (2022). Effect of drying methods and storage with agro-ecological conditions on phytochemicals and antioxidant activity of fruits: a review. Critical Reviews in Food Science and Nutrition, 62, 353–361. https://doi.org/10.1080/10408398.2020.1816891 DOI: https://doi.org/10.1080/10408398.2020.1816891

Wallis, T. E. (1985). Text book of pharmacognosy (5th ed., p. 652). New Delhi, India: CBS Publishers and Distributors.

Yan, Z., Gallagher, M. J. S., & Oliveira, F. A. R. (2008). Shrinkage and porosity of banana, pineapple and mango slices during air-drying. Journal of Food Engineering, 84, 430-440. doi:10.1016/j.jfoodeng.2007.06.004. DOI: https://doi.org/10.1016/j.jfoodeng.2007.06.004

Yamagar, S., & Borkar, S. (2018). Comparative study of physical properties of Nutmeg (Myristica fragrans Houtt.) of different varieties. International Journal of Chemical Studies, 6(6), 2561-2566.

Zeng, Z., Han, C., Wang, Q., Yuan, H., Zhang, X., & Li, B. (2024) Analysis of drying characteristic, effective moisture diffusivity and energy, exergy and environment performance indicators during thin layer drying of tea in a convective-hot air dryer. Frontiers in Sustainable. Food Systems, 8, 1371696. doi: 10.3389/fsufs.2024.1371696. DOI: https://doi.org/10.3389/fsufs.2024.1371696

Downloads

Published

How to Cite

License

Copyright (c) 2025 Journal of Experimental Biology and Agricultural Sciences

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.