Partial Purification of Extracellular Amylase From Halotolerant Actinomycetes Streptomyces brasiliensis MML2028

DOI:

https://doi.org/10.18006/2022.10(5).1053.1068Keywords:

Amylase, Halophilic, NaCl, Streptomyces, Dinitro salicylic acidAbstract

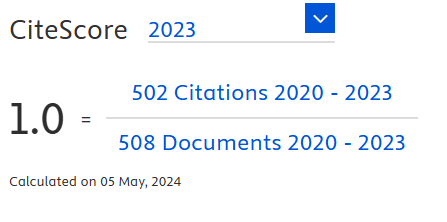

Amylase is considered as an industrially important enzyme as it occupies the most important function in the food, paper, and pharmaceutical industries. The present study is concerned with the optimization, production and partial purification of halotolerant amylase from newly isolated Streptomyces brasiliensis MML2028, from Kelambakkam salt pan, Tamil Nadu, India. The primary screening was carried out by well diffusion assay to find the zone of lysis. The assay was observed for each media optimization by measuring the release of reducing sugar (RS) by the 3,5 dinitro salicylic acid (DNS) method and expressed in the international unit (UI). Ammonium sulphate precipitation was used to partially purify the enzyme and then lyophilized. SDS-PAGE was performed to identify the molecular weight. The production medium was optimized with 1% of the starch substrate, 3% of NaCl at 24˚C and pH 9, and incubation of 9 days. The total activity of the partially purified α-amylase was observed to be 1806.9U/mL. The partially purified enzyme was more active with 3% NaCl, pH 8, and 24˚C which is known to be a halotolerant alkaline α-amylase. The enzyme showed tolerance towards magnesium, manganese ions, Triton x-100, and urea. De-inking of α-amylase showed good results proving that the enzyme activity is more efficient. Hence, the alkaliphilic amylase from Halotolerant actinomycetes S. Brasiliensis MML2028 could be a better microbial source that can be used in many industries, especially in paper and textiles.

References

Abdullah, R., Shaheen, N., Iqtedar, M., Naz, S., & Iftikhar, T. (2014). Optimization of cultural conditions for the production of alpha amylase by Aspergillus Niger (BTM-26) in solid state fermentation. Pakistan Journal of Biological Sciences, 46, 1071-1078.

Abdur Rahman, M.A., Zafrul Azam, A.T.M., & Gafur, M.A. (2000). In vitro antibacterial principles of two flavonoids and extracts from Clerodendrum indicum linn. Pakistan Journal of Biological Sciences, 3, 1769-1771. DOI: https://doi.org/10.3923/pjbs.2000.1769.1771

Arauza, L. J., Jozalaa, A. F., Mazzolab, P. G., & Penna, T.C.V. (2009). Nisin biotechnological production and application: a review. Trends Food Science and Technology, 20, 146-154. DOI: https://doi.org/10.1016/j.tifs.2009.01.056

Asad, W., Asif, M., & Rasool, S.A. (2011). Extracellular enzyme production by indigenous thermophilic bacteria: partial purification and characterization of α-amylase by Bacillus sp. WA21. Pakistan Journal of Biological Sciences, 43, 1045-1052.

Ashabil, A., Burhan, A., Hatice, K., Sadik, D., & Omer, Ç. (2008). Highly Thermostable and Alkaline Α-Amylase from A Halotolerant alkaliphilic Bacillus Sp. Ab68. Brazilian Journal of Microbiology, 39, 547-553. DOI: https://doi.org/10.1590/S1517-83822008000300027

Asrat, B., & Girma, A. (2018) Isolation, production and characterization of amylase enzyme using the isolate Aspergillus niger FAB-211. The International Journal for Biotechnology and Molecular Biology Research, 9, 7-14. DOI: https://doi.org/10.5897/IJBMBR2018.0289

Balakrishnan, M., Jeevarathinam, G., Kiran, S.K., Iniyakumar, M.S.U. (2021). Optimization and scale-up of α-amylase production by Aspergillus oryzae using solid-state fermentation of edible oil cakes. BMC Biotechnology, 21, 33-38. DOI: https://doi.org/10.1186/s12896-021-00686-7

Becker, B., Gordon, R. E., Lechevalier, H. A., & Lechevalier, M. P. (1964).Rapid differentiation between Nocardia and Streptomyces by paper chromatography of whole cell hydrolysates. Applied Microbiology, 12, 421-423. DOI: https://doi.org/10.1128/am.12.5.421-423.1964

Bhanu, S., Dharmendra Kumar, N., Alina, M., Anju, P., Roshani, N.P., & Sagar A. (2021). Isolation and Characterization of Potential Antibiotic-producing actinomycetes from water and soil sediments of different regions of Nepal. International Journal of Microbiology, 2021: 5586165. DOI: https://doi.org/10.1155/2021/5586165

Bradford, M.M. (1976). A rapid and sensitive method for the quantification of microgram quantities of protein utilizing the principle of protein-dye binding. Analytical Biochemistry, 72, 248-254. DOI: https://doi.org/10.1016/0003-2697(76)90527-3

Buchanan R. E., & Gibbons, N.E. (1974). Bergey’s manual of determinative bacteriology. 8th Edition, Williams and Wilkins, Baltimore.

Chao-Hsun, Y., & Wen-Hsiung, L. (2004). Purification and properties of a maltotriose-producing Alpha amylase from Thermobifida fusca. Enzyme and Microbial Technology, 35, 254-259. DOI: https://doi.org/10.1016/j.enzmictec.2004.05.004

Chen, X., Jiang, Y., Li, Q., Han, L., & Jiang, C. (2016). Molecular phylogenetic identification of actinobacteria. In D. Dhanasekaran, & Y. Jiang (eds) Actinobacteria. Basics and Biotechnological Applications, 56, 141–174. DOI: https://doi.org/10.5772/62029

Chimata, M. K., Chetty, C. S., & Suresh, C. (2011). Fermentative Production and Thermostability Characterization of α Amylase from Aspergillus Species and Its Application Potential Evaluation in Desizing of Cotton Cloth. Biotechnology Research International, 2011, 323891. https://doi.org/10.4061/2011/323891. DOI: https://doi.org/10.4061/2011/323891

Demirkan, E., Sevgi, T., & Başkurt, M., (2017). Optimization of physical factors affecting the production of the α-amylase from a newly isolated Bacillus sp. M10 strain. Karaelmas Fen ve Mühendislik Dergisi, 7, 23–30.

Djebbah, F.Z., Belyagoubi, L, Abdelouahid, D.E., Kherbouche, F., Al-Dhabi, N.A., Arasu, M.V., Ravindran, B. (2021). Isolation and characterization of novel Streptomyces strain from Algeria and its in-vitro antimicrobial properties against microbial pathogens. Journal of Infection and Public Health, 14, 1671-1678. DOI: https://doi.org/10.1016/j.jiph.2021.09.019

Eman, A.E., Mohsen, S.A., Ebtsam, M.E., Saadia, M.H., & Fawkia, M.E (2018). Production and optimization of α-amylase from thermo-halophilic bacteria isolated from different local marine environments. Bulletin of the National Research Centre, 42, 31-37. DOI: https://doi.org/10.1186/s42269-018-0033-2

Green, A.A., & Hughes, W.L. (1955). Protein solubility on the basis of solubility in aqueous solutions of salts and organic solvents. Methods in Enzymology, 1, 67-90. DOI: https://doi.org/10.1016/0076-6879(55)01014-8

Grootegoed, J.A., Lauwers, A.M., & Heinen, W. (1973). Separation and partial purification of extracellular amylase and protease from Bacillus caldolyticus. Archives of Microbiology, 90, 223-232. DOI: https://doi.org/10.1007/BF00424974

Haq, S.A., Javed, M.M., Hameed, U., Saleem, A., Adnan, F. & Qadeer, M.A. (2010). Production of alpha amylase from a randomly induced mutant strain of Bacillus Amyloliquefaciens and its application as a desizer in textile industry. Pakistan Journal of Botany, 42, 473-484.

Jagan Mohan, Y.S.Y.V., Sirisha, B., Prathyusha, K., & Pola, S.R. (2014). Isolation, screening and characterization of actinomycetes from marine sediments for their potential to produce antifungal agents. Global Journal of Biology Agriculture and Health Sciences, 3, 131-137.

Krishnakumar, S., Dooslin Mercy, B.V., & Premkumar, J. (2015). Production of alpha amylase by salt-tolerant actinomycetes Streptomyces sp. SBU3 isolated from marine sponge. Indian Journal of Marine Science, 44, 583-588.

Kundu, S. (2006). Isolation and identification of actinomycetes from estuarine fishes and optimization of-amylase enzyme. M. Phil. Thesis submitted to the Annamalai University, India.

Laemmli, U.K. (1970). Cleavage of structural proteins during the assembly of the head of becteriophage T4. Nature, 227, 680-685. DOI: https://doi.org/10.1038/227680a0

Laidi, R.F., Sifour, M., Sanker, M., & Hocine, H. (2008). A new actinomycete strain SK4-6 producing secondary metabolite effective against methicillin-resistnant Staphylococcus aureus. World Journal Microbiology and Biotechnology, 24, 2235-2241. DOI: https://doi.org/10.1007/s11274-008-9735-1

Lechevalier, M.P, & Lechevalier, H. (1970). Chemical composition as a criterion in the classification of aerobic actinomycetes. International Journal of Systematic and Evolutionary Microbiology, 20, 435-443. DOI: https://doi.org/10.1099/00207713-20-4-435

Li, Q., Chen, X., Jiang, Y., & Jiang, C. (2016). Morphological identification of actinobacteria. In D., Dhanasekaran, & Y., Jiang (eds) Actinobacteria-Basics and Biotechnological Applications. Intech Open, London. DOI: https://doi.org/10.5772/61461

Mohamed, H.A., Mohammad, R.A., Mahmoud, S. K., & Moaz, M.H. (2021). Production and Partial Characterization of α-Amylase Enzyme from Marine Actinomycetes. BioMed Research International, 5289848, https://doi.org/10.1155/2021/5289848. DOI: https://doi.org/10.1155/2021/5289848

Mohamed, S.A., Azhar, E.I., Ba-Akdah, M.M., Tashk, N.R., & Kumosani T.A. (2011). Production, purification and characterization of α-amylase from Trichoderma harzianum grown on mandarin peel. African Journal of Microbiology Research, 5, 930-940. DOI: https://doi.org/10.5897/AJMR10.890

Monciardini, P., Sosio, M., Cavaletti, L., Chiocchini, C., & Donadio, S. (2002). New PCR primers for the selective amplification of 16S rDNA from different groups of actinomycetes1. FEMS Microbiology Ecology, 42, 419-429. DOI: https://doi.org/10.1111/j.1574-6941.2002.tb01031.x

Nipkow, A., Shen, G.J., & Zeikus, J.G. (1989). Continuous production of thermostable-amylase with Clostridium thermosulfurogenes. Applied Environmental Microbiology, 55, 689-694. DOI: https://doi.org/10.1128/aem.55.3.689-694.1989

Oskay, A., Usame, T., & Cem, A. (2004). Antibacterial activity of some actinomycetes isolated from farming soils of Turkey Mustafa. African Journal of Biotechnology, 3, 441-446. DOI: https://doi.org/10.5897/AJB2004.000-2087

Plumer, D.T. (1978). An introduction to practical biochemistry. McGraw-Hill, London, pp. 47–98.

Poornima, R., Maloy, K.S., Sivakumar, K., & Pushpavalli, V. (2008). Optimization of amylase production by actinomycete strain AE-19 isolated from shrimp pond. Trends in Applied Sciences Research, 3, 45-52. DOI: https://doi.org/10.3923/tasr.2008.45.52

Prabavathy, V. R., Mathivanan, N., & Murugesan, K. (2006). Control of blast and sheath blight diseases of rice using antifungal metabolites produced by Streptomyces sp. PM5. Biological Control, 39, 313-319. DOI: https://doi.org/10.1016/j.biocontrol.2006.07.011

Ratanakhanokchai, K., Kaneko, J., Kamio, Y., & Izaki, K. (1992). Purification and properties of a maltotetraose- and maltotriose-producing amylase from Chloroflexus aurantiacus. Applied Environmental Microbiology, 58, 2490-2494. DOI: https://doi.org/10.1128/aem.58.8.2490-2494.1992

Ray, R.C., & Kar, S. (2009). Statistical optimization of α-amylase production by Bacillus brevis MTCC 7521 in solid-state fermentation using cassava bagasse. Biologia, 64, 864-870. DOI: https://doi.org/10.2478/s11756-009-0160-1

Roy, J.K., Rai, S.K., & Mukherjee, A.K. (2012). Characterization and application of a detergent-stable alkaline alpha-amylase from Bacillus subtilis strain AS-S01a. International Journal of Biological Macromolecules, 50, 219-229. DOI: https://doi.org/10.1016/j.ijbiomac.2011.10.026

Roy, K. K., Mishra, A. & Bhattacharyya, N. (2014). Partial purification and characterization of amylase from a newly isolated Bacillus megaterium strain KAN1 from fermented Rice Handia. American Journal of Current Microbiology, 2, 1-5.

Sathi, Z.S., Rahman, M.A.A., & Gafur, M.A. (2001). Identification and in vitro anti-microbial activity of a compound isolated from Streptomyces species. Pakistan Journal of Biological Sciences, 4, 1523-1525. DOI: https://doi.org/10.3923/pjbs.2001.1523.1525

Saxena A., & Singh Chauhan P., (2017). Role of various enzymes for deinking paper: a review. Critical Reviews in Biotechnology, 37, 598-612. DOI: https://doi.org/10.1080/07388551.2016.1207594

Saxena, R.K., Dutt, K., Agarwal, L., & Nayyar, P. (2007). A highly thermostable and alkaline amylase from a Bacillus sp. PN5. Bioresource Technology, 98, 260-265. DOI: https://doi.org/10.1016/j.biortech.2006.01.016

Simair, A. A., Qureshi, A. S., Khushk, I., Ali, C. H., et al. (2017). Production and Partial characterization of α-amylase enzyme from Bacillus sp. BCC 01-50 and potential applications. BioMed Research International, 9173040 doi: 10.1155/2017/9173040. DOI: https://doi.org/10.1155/2017/9173040

Singh, P., Sharma, R., & Singh, R. (2017). Maximum α-Amylase Production by Molecular and Biochemical Characterized Soil Microorganism. Journal of Biotechnology & Biomaterials, 7, 266- 272. DOI: https://doi.org/10.4172/2155-952X.1000266

Sodhi, H. K., Sharma, K., Gupta, J. K., & Soni, S. K. (2005). Production of a thermostable α-amylase from Bacillus sp. PS-7 by solid state fermentation and its synergistic use in the hydrolysis of malt starch for alcohol production. Process Biochemistry, 40, 525–534. DOI: https://doi.org/10.1016/j.procbio.2003.10.008

Stamford, T.L., Stamford, N.P., Coelho, L.C, & Araujo, J.M. (2001). Production and characterization of a thermostable alpha-amylase from Nocardiopsis sp. endophyte of yam bean. Bioresource Technology, 76, 137-141. DOI: https://doi.org/10.1016/S0960-8524(00)00089-4

Suman, S., & Ramesh, K. (2010). Production of a thermostable extracellular amylase from thermophilic Bacillus species. Journal of Pharmaceutical Sciences and Research, 2, 149-154.

Valsalam, S., Agastian, P., Esmail, G.A., Mohammed Ghilan, A.K., Al-Dhabi, N.A., Valan Arasu, M. (2019). Biosynthesis of silver and gold nanoparticles using Musa acuminatacolla flower and its pharmaceutical activity against bacteria and anticancer efficacy. The Journal of Photochemistry and Photobiology: Biology, https://doi.org/10.1016/j.jphotobiol.2019.111670. DOI: https://doi.org/10.1016/j.jphotobiol.2019.111670

Vidyalakshmi, R., Paranthaman, R., & Indhumathi, J. (2009). Amylase production on submerged fermentation by Bacillus sp. World Journal of Chemistry, 4, 89-91.

Weisburg, W.G., Barns, S.M., Pelletier, D.A., & Lane, D.J.J (1991).16S ribosomal DNA amplification for phylogenetic study. Bacteriology, 173, 697-703. DOI: https://doi.org/10.1128/jb.173.2.697-703.1991

Yanti, H., Setyawati, T. R., & Kurniatuhadi, R. (2019). Composition and Characterization of Actinomycetes Isolated from Nipah Mangrove Sediment, Gastrointestinal and Fecal Pellets of Nipah Worm. In IOP Conference Series: Earth and Environmental Science, Volume 550, International Conference of Mangroves and Its Related Ecosystems 2019 held on 21 - 23 August 2019, at Purwokerto, Indonesia. DOI: https://doi.org/10.1088/1755-1315/550/1/012003

You, J. L., Cao, L. X., Liu, G. F., Zhou, S. N., Tan, H. M & Lin, Y. C, (2005). Isolation and characterization of actinomycetes antagonistic to pathogenic Vibrio spp. from nearshore marine sediments. World Journal of Microbiology and Biotechnology, 21, 679-682. DOI: https://doi.org/10.1007/s11274-004-3851-3

Zhu, D., Adebisi, W.A., Ahmad, F., Sethupathy, S., Danso, B., & Sun, J. (2020). Recent Development of Extremophilic Bacteria and Their Application in Biorefinery. Frontiers in Bioengineering and Biotechnology, 8, 483-488. DOI: https://doi.org/10.3389/fbioe.2020.00483

Downloads

Published

How to Cite

License

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.